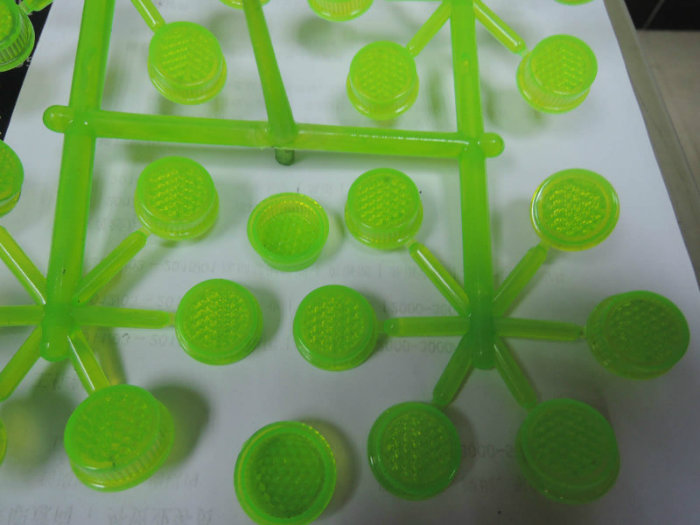

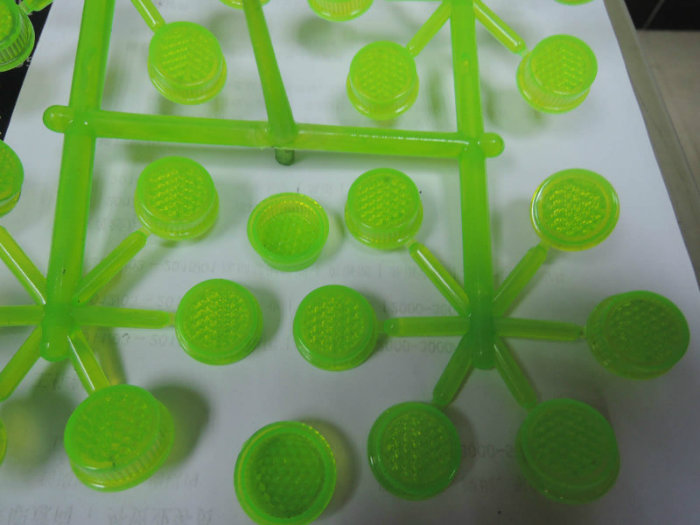

Model NO.: LL33 Surface Finish Process: According to Your Requirements Plastic Material: According to Your Requirements Application: Car, Household Appliances, Furniture, Commodity, Home Use Design Software: Ug,Proe,Auto CAD Certification: SGS Customized: Customized Mould Life: 50,000-3000,000 Times Gate: Submarine Gate, Side / Edge Gate,etc Thickness: According to The Moulds Request Size: According to Customers′ Sizes Cavity: Single-Cavity and Multi Cavity Specification: According To Moulds Size HS Code: 8480710090 Shaping Mode: Injection Mould Mould Cavity: Multi Cavity Process Combination Type: Injection Mould Runner: Hot Runner Installation: Mobile Standard: HASCO Item: Mold Mould Steel: Nak55,Nak80, 2738, 2316, H13, 718,etc Function: Can Inject Any Plastic Product Material: Steel Customize: Agreement Trademark: YW Origin: Dongguan of China Light weight heat resistant materials PEEK plastic parts

Dongguan Universe Plastic Co.,Ltd is a factory located in Dongguan, Guangdong, china. with over 10 years OEM/ODM experience in custom plastic injection molding products. Company with self owned mould workshop, 10 sets plastic injection machine, 50 workers, 5 designers to promote your new brands and products finish smoothly.

Specifications

Code | Basic information | answers |

| 1 | Mold design | According to customer product to design |

| 2 | Mold making | Plastic mold steel material,mold base,CNC machine,wire cut machine,EDM machine,grinder machine,assember,fit mold |

| 3 | Soft ware | CAD/CAM/CAE/UG/PROE/CAD/CAXA etc |

| 4 | process | CNC, High speed carve, E.D.M, Wire cut, Drill, Injection etc |

| 5 | Cavity | Single-cavity and Multi cavity |

| 6 | Use and manufacture | According to product precision to choice the different model

80T,120T,250T,450T,800T injection machine |

| 7 | Injection plastic type | Pinpoint,turnel,direct |

| 8 | Mold life | 50,000-3000,000 times |

| 9 | Mold steel | NAK55,NAK80, 2738, 2316, H13, 718,718H, S136,S136H, SKD61, P20,etc |

| 10 | Gate | Submarine gate, Side / Edge gate, Direct gate, Self-cutting gate etc

|

What we can do ?

1.

Plastic Injection Mold2. Plastic injection molded products

How to make plastic injection mold ?

You know when we want to make a new plastic products, we have to make the plastic injection mold firstly. In order to make the mold, we need 2 things as below:

1. 3D drawing.

2. If don't have drawing, we need the samples.

Contact us

Any further questions please send inquiry to us now, we will reply you soon. hope to build good business relationship with your company.

Contact us if you need more details on Peek Plastic Parts. We are ready to answer your questions on packaging, logistics, certification or any

Other aspects about Heat Resistant Parts、Heat Resistant Peek. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic Injection Mold