Model NO.: universe 221 Surface Finish Process: Polishing Plastic Material: 718,718h, S136,S136h, SKD61, P20,etc Application: Car, Household Appliances, Furniture, Commodity, Home Use Design Software: Ug /PRO-E /Autocad Certification: SGS Customized: Customized Use: Injection Molding Plastic Products Material: Steel Thickness: According to The Moulds Request Customize: Agreement Specification: According To Moulds Size HS Code: 4002111000 Shaping Mode: Injection Mould Mould Cavity: Single Cavity/Multi Cavity Process Combination Type: Single-Process Mode Runner: Cold Runner/Hot Runner Installation: Fixed Standard: HASCO Place of Origin: Dongguang City of China Type: Injection Molding Tools Manufaturing: OEM Size: According to Product Specifications Trademark: Universe Origin: Dongguan of China

OEM Electrical Junction box Injection Mould

Our advantages:

1. Manufature

Plastic Injection Mold and injection molding plastic products.

2. Export plastic mold and plastic products to various places around the world.

Dongguan Universe Plastic Co.,Ltd was founded in 2000 year, located in Chang'an Town,

Dongguan City, near Shenzhen and Guangzhou City.We can independently complete product design, mold manufacturing, processing one stop service system to meet customer ideas and concepts into a wealth of capabilities.

*** Our companies on behalf of the customer to complete products injection molding - Assembly - Color Printing - Screen Printing - trademark production - hardware support - export agent and

Other processes.

*** If you are not satisfied with the sample, we can send the sample to you again for free.

***If you received the goods are not the same as the sample, we accept the goods refunded ,and all the shipping freight charge at our side.Also we will refund all the money to your account.

***If you found have some parts of bad quality products , then we will accept to send thegood quality one to you again.

***If you meet some shipping transportation problems,we can help you to solve at first time.

Technicial data for injection mould:

Code | Basic information | answers |

| 1 | Mold design | According to customer product to design |

| 2 | Mold making | Plastic mold steel material,mold base,CNC machine,wire cut machine,EDM machine,grinder machine,assember,fit mold |

| 3 | Soft ware | CAD/CAM/CAE/UG/PROE/CAD/CAXA etc |

| 4 | process | CNC, High speed carve, E.D.M, Wire cut, Drill, Injection etc |

| 5 | Cavity | Single-cavity and Multi cavity |

| 6 | Use and manufacture | According to product precision to choice the different model

80T,120T,250T,450T,800T injection machine |

| 7 | Injection plastic type | Pinpoint,turnel,direct |

| 8 | Mold life | 50,000-3000,000 times |

| 9 | Mold steel | NAK55,NAK80, 2738, 2316, H13, 718,718H, S136,S136H, SKD61, P20,etc |

| 10 | Gate | Submarine gate, Side / Edge gate, Direct gate, Self-cutting gate etc

|

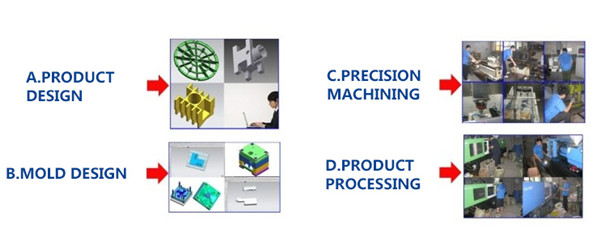

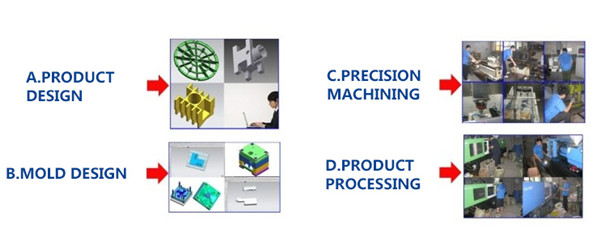

Plastic Products Manufacturing Process:

Mouding for Plastic Products:

High Quality Plastic Injection Molds:

Packaging the molds:

Our company:

Looking forward to let us know in further question,please contact us at once!

Contact us if you need more details on Electrical Injection Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about OEM Junction Box、OEM Injection Mould. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic Injection Mold